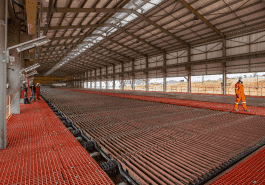

At the plant, they go through several processing stages, including leaching and counter-current decantation.

The residues are sent for neutralization, and the tailings are transferred to tailings ponds after neutralization.

At the cobalt plant, cobalt hydroxide is obtained after a series of purification phases.